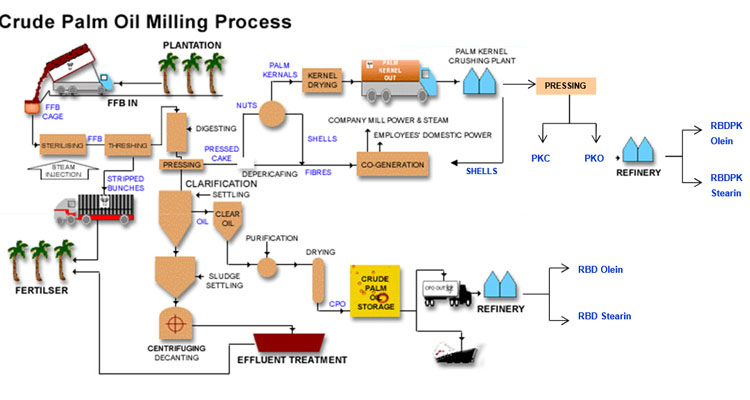

Palm Oil Mill Process Description

Palm oil mill buyer.

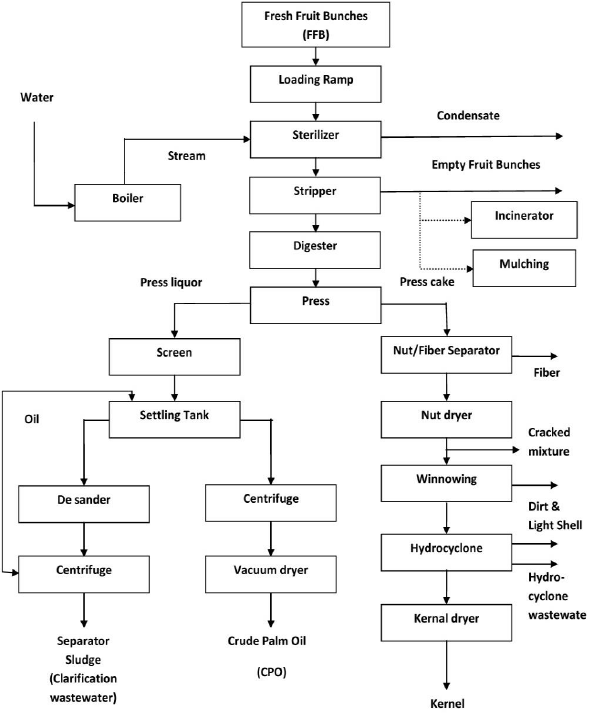

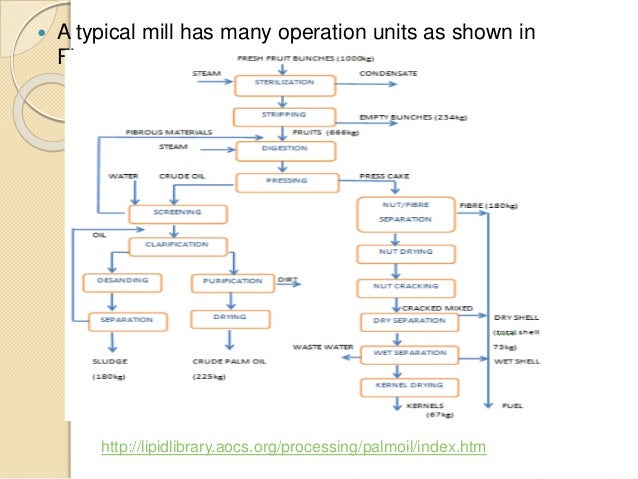

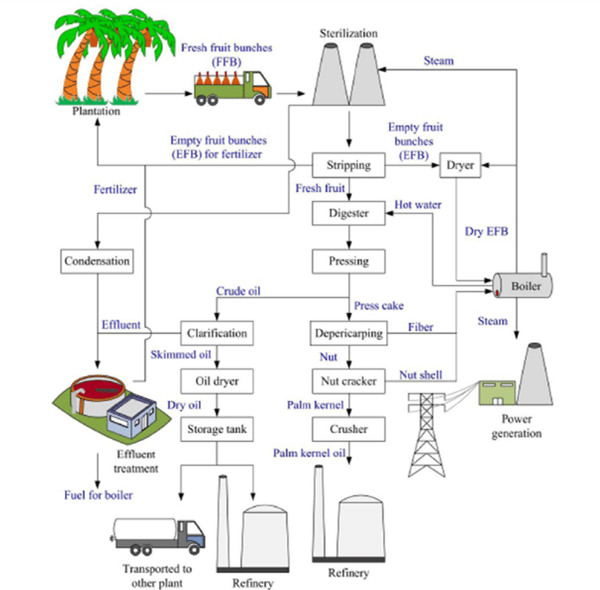

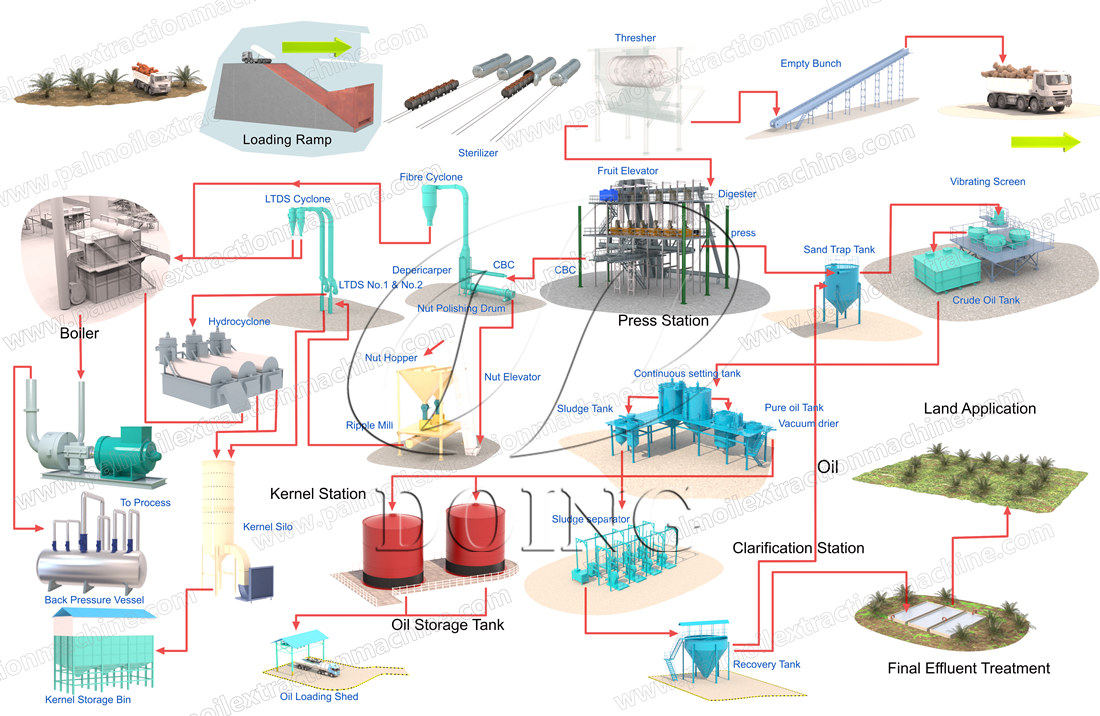

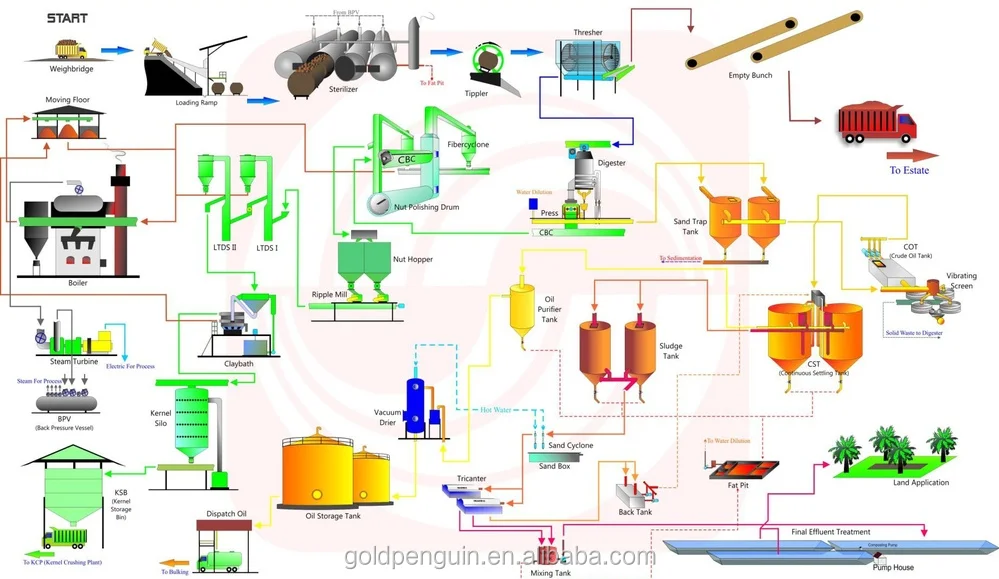

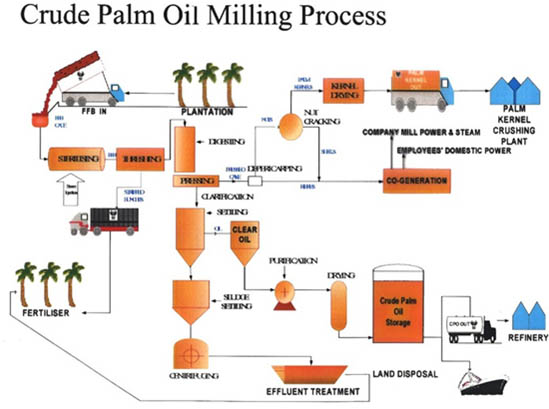

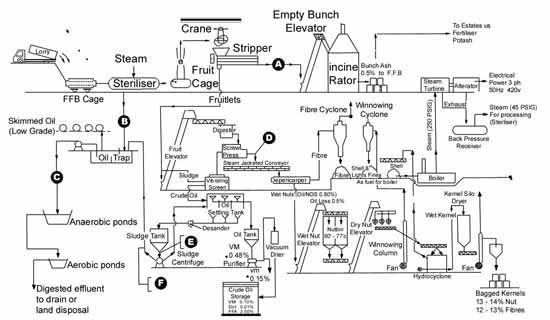

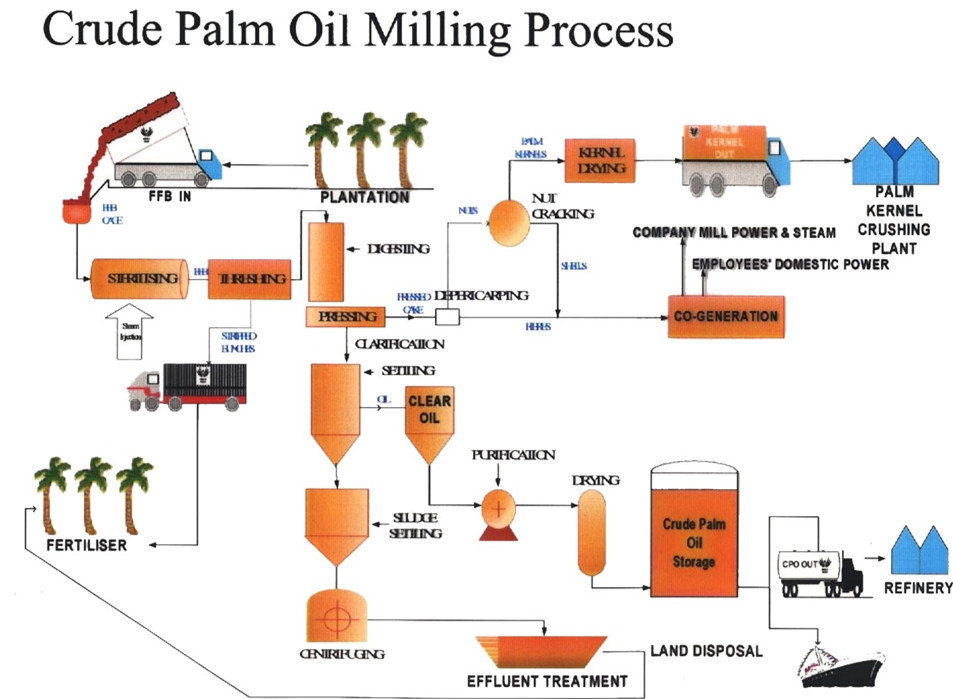

Palm oil mill process description. After the removal of oil the waste water effluent is discharged from the mill. At the extraction mill the upstream production process consists of a number of process steps for production of cpo and kernel corley et al 2003. Introduction of the palm oil milling process fresh fruit bunch palm oil cpo crude palm oil is extracted from ffb fresh fruit bunch by mechanical process where a mill commonly handles 45 to 100 mt per hour of ffb the modern palm oil mill of today is based predominantly on concepts developed in the early 50s. Research and development work in many disciplines biochemistry chemical and mechanical engineering and the establishment of plantations which provided the opportunity for large scale fully mechanised processing resulted in the evolution of a sequence of processing steps designed to extract from a harvested oil palm bunch a.

Palm oil mill process and palm kernel crushing process. Before offloading the fruit is weighed at the electronic weighbridge at the entrance gate. This effluent contains particles of vegetable matter and needs to be treated before discharge to the environment. 1 general processing description.

Moisture 0 18 dirt 0 02 dobi 2 3 ffa 3. Palm oil processing 3. Cpo cpo storage storage tank tank function to keep cpo before delivery to buyer palm oil mill. Fresh fruit bunches ffb from the plantations are offloaded daily at the factory s offloading bay.

Separately fiber and nut to clean up nut from fiber. Fibre fibre fibre cyclone cyclone. Polishing polishing drum drum function.